A central solution

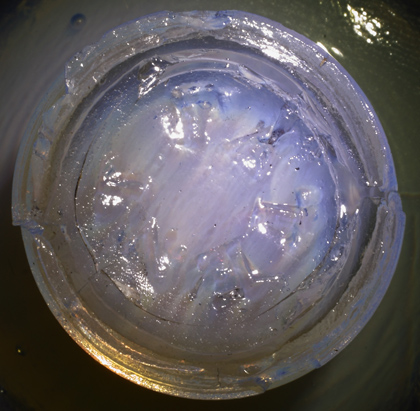

Subtle differences between the centers of two miniature drawer pulls reveal how a mold maker solved a tricky problem — creating a mold with a fixed volume, to be filled with varying quantities of glass.

Pressed glass knobs play a special role in glass history.

They were among the earliest machine-pressed objects, and also the subject of a well-documented legal battle involving several early inventors of pressing technology.

In 1829 Deming Jarves of Sandwich, Massachusetts, patented this pressed glass knob which, for the first time, had an integral threaded shank, created in the mold as the knobs were pressed. Other early knobs were pressed with a hole through their centers, allowing them to be fastened to furniture with metal bolts. The word "PATENT" appears prominently at the end of the shank of larger versions of Jarves' knobs:

Due to the patent office fire of 1836 the precise details of Jarves' patent have been lost, together with records of other early pressing-related patents. Was his invention limited to the integral threaded shank? Did it also explain how to cope, in such a small, precise mold, with the varying quantities of glass dropped into it before each pressing?

Each miniature pull has a clear, continuous mold seam running from rim to rim down its side, over its thread, across its base, and back down the other side, resulting from a hinged, two part mold that was a tight little package, with little room for variation.

However, it was simply impossible to drop precise quantities of hot glass into the mold, to fill it just perfectly. Varying quantities had to be accommodated somehow.

Viewed closely, side-by-side, the solution is apparent in their centers:

The plunger was forced down into the center of the knob, through the middle of a fixed cap ring which molded the outer edge of its top. With a little less glass dropped into the mold, the plunger could push down further and the knob's center was recessed:

With a little more glass, the plunger stopped sooner and the design from the base of the plunger appears raised. On this knob it even competes with the raised parts of the surrounding design:

From a distance, however, a reasonable amount of variation is hidden, thanks to the central solution as well as camouflage provided by the surrounding raised design.